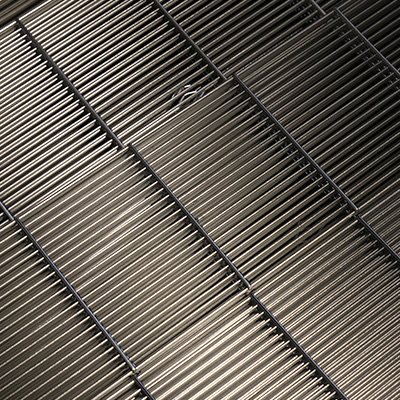

Anodizing, the deposition of an antioxidant layer on a metal

Anodizing is a process that consists of depositing a layer of protective oxide on the surface of a metal.

The process of oxidation is found in some metals even in the natural way, as for aluminum or stainless steel. The natural process, however, takes several years to reach a conclusion, and very often is invalidated by some factors that affect its success.

What is it for

For a correct anodizing process it is necessary that the protective film that covers the metal is dense and non-porous.

Only in this way can the layer be regenerated in the event of a loss of balance.

Another characteristic is the thickness: thicker is the layer, greater is the possibility that it will be destroyed.

Artificial anodising is therefore an excellent method of ensuring resistance to corrosion.

Before proceeding, however, it is necessary to ensure that you have carried out a thorough and adequate cleaning of the object.

Metal

that we treat

Bama precedes anodising with degreasing, pickling and passivation.

These are fundamental operations to obtain a precise result. If an object has residues of grease, in fact, the process of anodizing will not be optimal for the lack of adhesion of the coating.

Similarly, the presence of small burrs in the absence of the pickling process would damage the subsequent finish and highlight the imperfections.

The actual anodizing process, on the other hand, consists in immersing the positively charged object in a tank containing an electrolyte. The electric current, passing through the liquid, reacts by depositing a layer of compact and protective oxide.

Corrosion resistance is therefore the main result achieved by anodizing. However, this technique is also used for other purposes: with anodising it is possible to apply high-quality decorative/aesthetic finishes. This process makes it possible to achieve a uniform surface.

In addition, the process can be accompanied by the addition of special colours, ranging from blue (as with titanium) to yellow and red.

Bama

Products

A deoxidant is a substance that has a special deep cleaning action, specific for residual oxides.