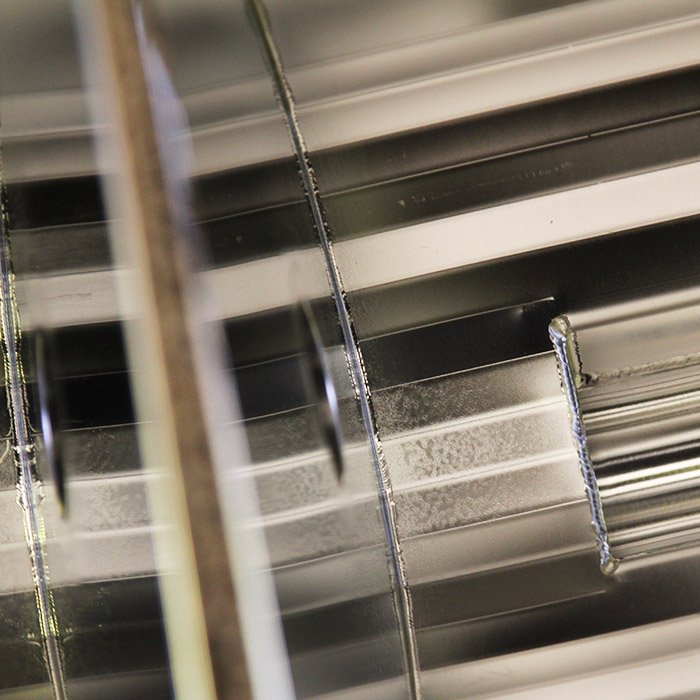

Electropolishing aluminum, removing a very thin layer from the surface of the metal

Bama has the technology but is not available on mass-produced products. Ad hoc projects can be considered according to the customer's needs.

Removing the thin layer

Inside the production site of Bama is carried out the treatment of electropolishing aluminum.

This process, usually carried out on stainless steel, is also applied to a material such as aluminium because of the many advantages it brings.

The electropolishing of aluminium is nothing more than the removal of a very thin layer from the surface of the metal.

The operation is not at harmful to the object; on the contrary, it eliminates all types of deburring and roughness, restoring a perfectly smooth and smooth surface, acting at a microscopic level.

The technique used for electropolishing aluminium is the immersion one.

The advantages of electropolishing

The electropolishing of aluminium considerably increases the resistance to corrosion of the material, allowing to multiply its uses and extending the life of the object.

Aluminium electropolishing is even more effective when preceded by processes such as degreasing, pickling and passivating. In fact, the latter have a preliminary function of deep cleaning (in the case of the first two) and protection (in the case of passivation).

In this way the object is presented for electropolishing aluminium without contaminants of any kind, and therefore best prepared to receive treatment.

The object is placed in a tank, inside a chemical solution generally formed by sulphuric and orthophosphoric acids, and connected to a positive pole.

A current flow causes the surface ions to become detached, thus smoothing out any difference in level.

This does not result in a loss of volume for the object: the layer removed has a thickness that varies between 5 and 15 microns.

The electropolishing process not only allows the surfaces to be polished, but also has a number of additional advantages.

First of all, it is in fact possible through this procedure to give the aluminium a valuable aesthetic result.

Like stainless steel, this phase of processing is particularly useful to take advantage of a product that is easy to clean and resistant to corrosion in a wide variety of areas, including pharmaceuticals, chemicals, medical and food.