Anodizing titanium, cover the metal with a protective layer consisting of oxides

Bama is one of the few companies able to offer a service of titanium anodizing.

The process

Bama is one of the few companies able to offer a service of titanium anodizing. This very particular procedure allows to carry out a protective measure against oxidation even on a material such as titanium. Titanium is an element of great technological value, because of its intrinsic properties of resistance to corrosion, such as stainless steel. It is widely used in various industrial sectors.

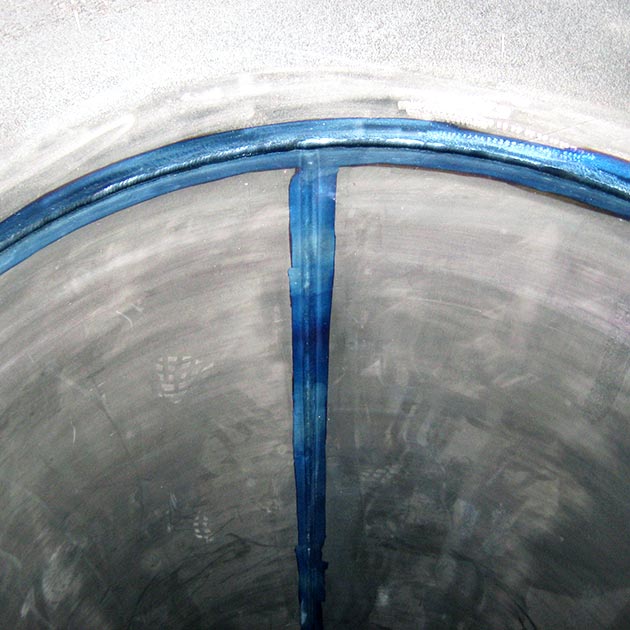

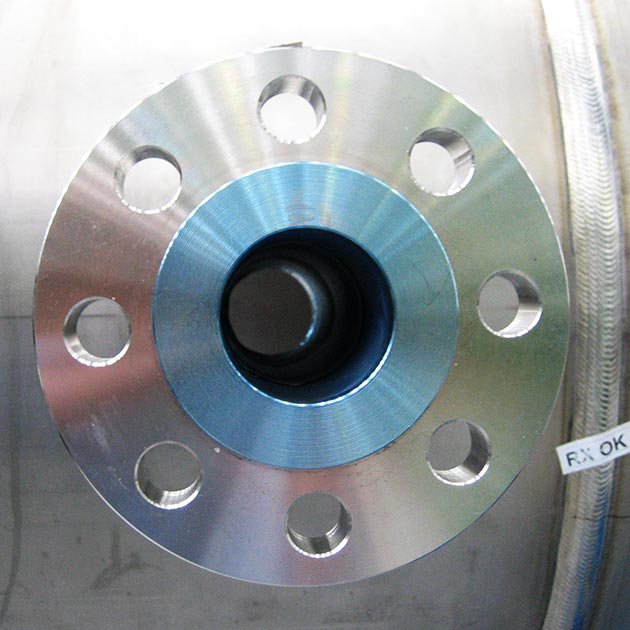

Titanium anodizing is therefore a process that aims to cover the metal with a protective layer consisting of oxides, which aims to prevent the risk of corrosion that the material may incur with the passage of time and with contact with elements such as air and water.

The procedure

It is thanks to this layer that a material such as titanium - already resistant to corrosion - increases this capacity, making it "impermeable" to wear and aggressive agents.

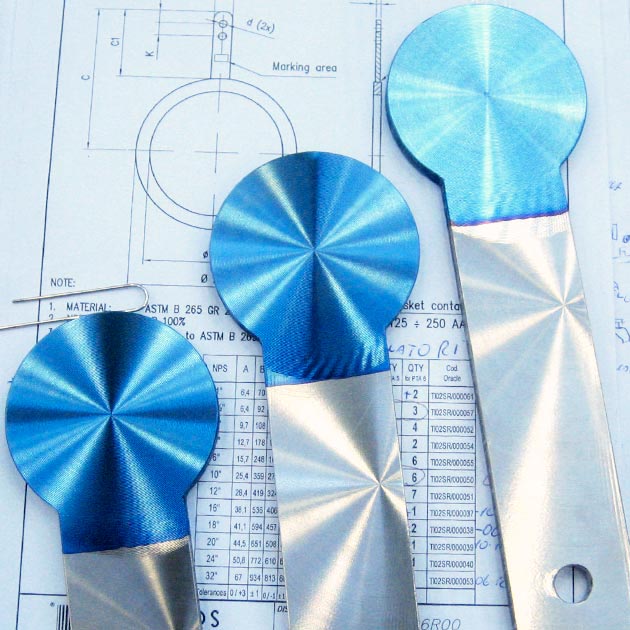

The particularity of titanium anodizing also lies in the possibility of proceeding to apply particular colours to the object. The process can in fact give the material a very wide range of colours and shades, ranging from blue to black, passing through all the other colours.

If blue is typically used in the chemical and petrochemical industry, for example, black is associated with the arms industry.

Just like other metals, titanium anodising must be preceded by some of the treatments that Bama offers as part of its services in order to be effective. Only by degreasing, for example, is it possible to remove those residues of grease in the presence of which the process of anodizing titanium would not take root.

Moreover, with pickling it is possible to carry out a deep cleaning by going to remove all the oxides deposited during the manufacturing processes.

Only after these treatments it is possible to proceed with titanium anodising.

During the process, the object comes into contact with water and other specific chemicals that combine to react to the current impulse coming from outside, releasing an oxidizing layer on the surface of the object.